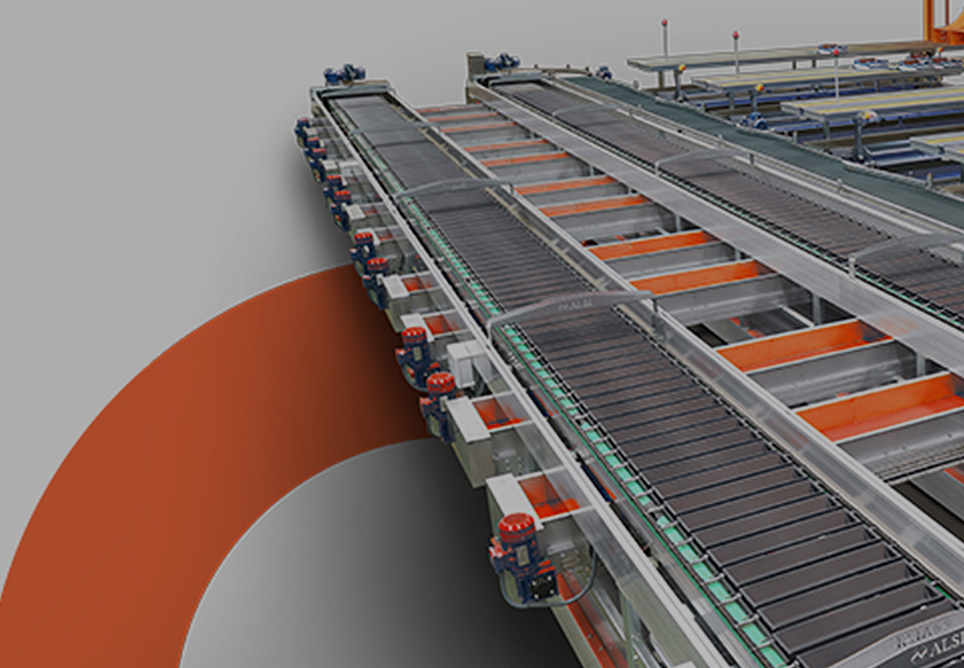

Intelligent size tracking system

A system that provides information on the weight, diameter, colour or length of products. Smart system for high-volume production, with an integrated electronic system that enables a complete control of the production according to quality standards. This electronic system integrates with each client’s database and management software.

Specifications

– Stainless steel and aluminium structure.

– Measurement methods that provide information on weight, diameter, colour or sweetness score of the product.

– Available for processing all types of fruit and vegetables.

– Up to 8 lines capacity.

– Approximately 1 gram accuracy.

– 7 to 15 products per second.

– Side, flat and brush unloading

– User interface through specific software for production statistics and system data.

– Intuitive touch screen for parameter setting.

– Fully equipped with Industry 4.0 technology.

Additional equipment

– Integration with traceability systems.

– Cup self-cleaning system.

– Automatic lubrication.

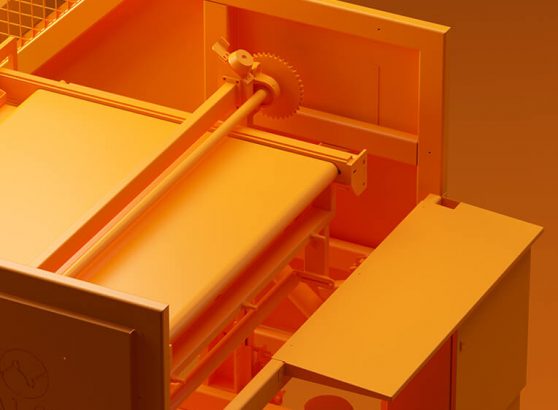

Size tracking system for long fruit

A system that provides information on the weight, diameter, colour or length and curvature of long fruit. It includes a sliding system for the product, ensuring the product’s quality and preventing damage. Its integrated electronic system provides an exhaustive control of production, according to quality standards. This electronic system is adapted to each client’s database and management software.

Specifications

– Stainless steel and aluminium structure.

– Up to 7 products per second with a production power of 2.2 kW.

– Available for processing all types of fruit and vegetables.

– Approximately 1 gram accuracy.

– User interface through specific software for production statistics and system data.

– Control system through PLC Programmable Logic Controller.

– Intuitive touch screen for parameter setting.

-Fully equipped with Industry 4.0 technology.

Additional equipment

– Label control.

– Traceability system interface.

– Cup self-cleaning system.

– Automatic lubrication.

– Synchronised feeding.

They already trust us